Product classification

- Description

-

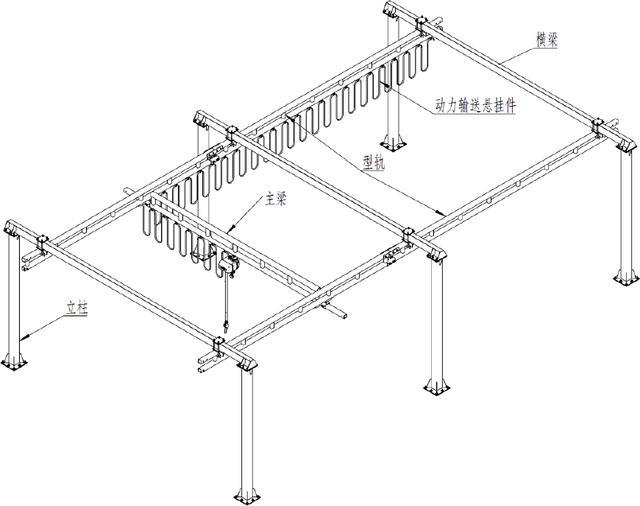

Self-supporting KBK crane:

The rigid light-duty crane adopts closed steel tracks and main beams using European technology, with modular production and assembly. It ensures reliable and stable quality, with a lifting capacity of up to 3200kg, suitable for a wide range of applications, especially modern machining, assembly, warehousing, and other advanced production lines. Its features are summarized as follows:

1. Reliable, stable, economical, and efficient

The tracks are made of high-strength steel, cold-rolled in one piece to avoid deformation from secondary welding. The closed design of the tracks effectively prevents dust on the rolling surface, thereby reducing resistance and wear between the trolley wheels and the tracks, making operation more flexible and extending service life. The simple structural design reduces the failure rate; the smooth wheel contact surface and unique wheel design ensure low running resistance and low noise; more convenient manual operation, overall low power, and low energy consumption (electric operation can save 40% energy compared to Soviet-style lifting equipment).

The rigid connection and unique guide wheel design ensure that the main beam does not tilt or shake under load or no load, thus ensuring precise positioning of the load.

The high-strength track and expandable truss structure design eliminate the need for additional I-beam suspension, thereby reducing overall weight, with a lifting capacity of up to 2000kg, economical and environmentally friendly. In particular, the optimization of the truss structure allows for spans of up to 9 meters, significantly reducing the number of columns or supports, minimizing spatial interference, and making the factory layout aesthetically pleasing and simple.

2. Strong adaptability and precise layout

Modular production and modular assembly can be precisely designed according to your actual needs, reducing idle equipment waste. All standard modules can be connected with bolts, allowing for adjustments, relocations, and modifications according to changing production needs.

The optimized structural design can provide self-supporting, suspended, and ultra-low clearance installation methods according to the existing factory structure and space requirements. For different working conditions, stainless steel tracks can be provided for clean spaces and food-grade tracks.

Related

Message

Please provide the following valid information and we will contact you as soon as possible.